Armor Shield has come up with a liquid formulation that coats fabrics to make surfaces more

hygienic

Covid-19 drove the need for innovative solutions to maintain sanitary environments. Leveraging their

research expertise, three researchers joined hands to create plant extract-based antiviral nano- formulation

for virus-free high-touch surfaces in critical areas like hospitals, schools and workplaces.

THE INVENTION

Armor Shiled Healthcare Innovations produces Armorfabrix antiviral liquid that when used in textile

manufacturing enhances quality, durability and anti- viral properties.

HOW IT STARTED

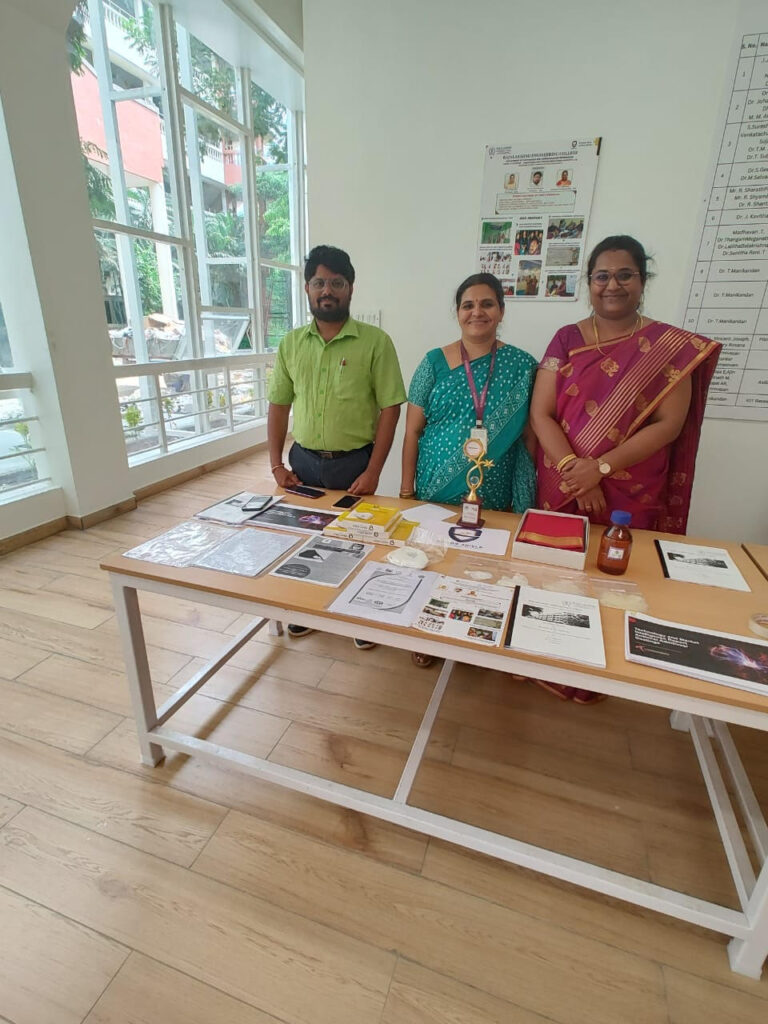

Two and half years ago, Dr. J Saranya, Dr. VS Selva Kumar and Dr. S Sugandhi, research scholars and

colleagues at a city engineering college attended an online seminar that encouraged them to think like

entrepreneurs. “We were all simultaneously researching products that can impart better health. We

decided to work on antiviral formulations that could be used in hospitals, clinics, hostels and hotels,” says

Saranya.

FIRST DRAFT

The trio pooled Rs 3.5 lakh each from their earnings to raise around Rs 10 lakh for research and

development and case studies. “Currently, we have a recurring demand of 1,000 liters per month from the

textile industry and we are also looking at similar solutions for medical devices such as blood collectors,”

she adds. The team is considering raising funds worth Rs 2 crore via co-operative society or industrial

bank to establish a full-fledged operation. The fact that the coat of formulation makes the fabric more

durable (1.5 times as compared to regular cloth) is what they think will fetch them more clients.

SOLUTIONS FOR ALL

The formulation given in a liquid form along with guidelines on how much to add to the fabric, at what

stage and at what temperation of manufacturing, can also be coupled with other mediums including

paints, leather and wooden laminates resulting in virus-free surfaces with improved texture. This ‘Make in

India’ technology uses organic nano compounds with benefits that include non-toxicity, higher stability

and increased shelf life on surfaces. The National Accreditation Board for Testing and Calibration

Laboratories (NABL) has validated their formulation.

“We decided to work on antiviral formulations that could be used in hospitals, clinics, hostels and hotels,”

- Dr Saranya

MILESTONES

Kanchipuram Silk Board and south Indian paint and leather manufacturers are part of their customer list.

“Our product has increased tensile strength with a soft texture of coated silk and cotton fibers. This

translates to more durability. The retention of antiviral properties goes beyond 20 washes. So a hospital

need not spend money changing its upholstery and linen every two years as our product has better

durability,” says Saranya.

THREE TAKEAWAYS

- Start with the end in mind and keep the customer’s needs and build your product and not build a product

and convince the customer to use it - Invest in a good team even before you make profits

- Focus on creating a good product and not on profit in the first few years

Price: On request based on the requirement

www.armorinno.com

Tel: 99623 84648